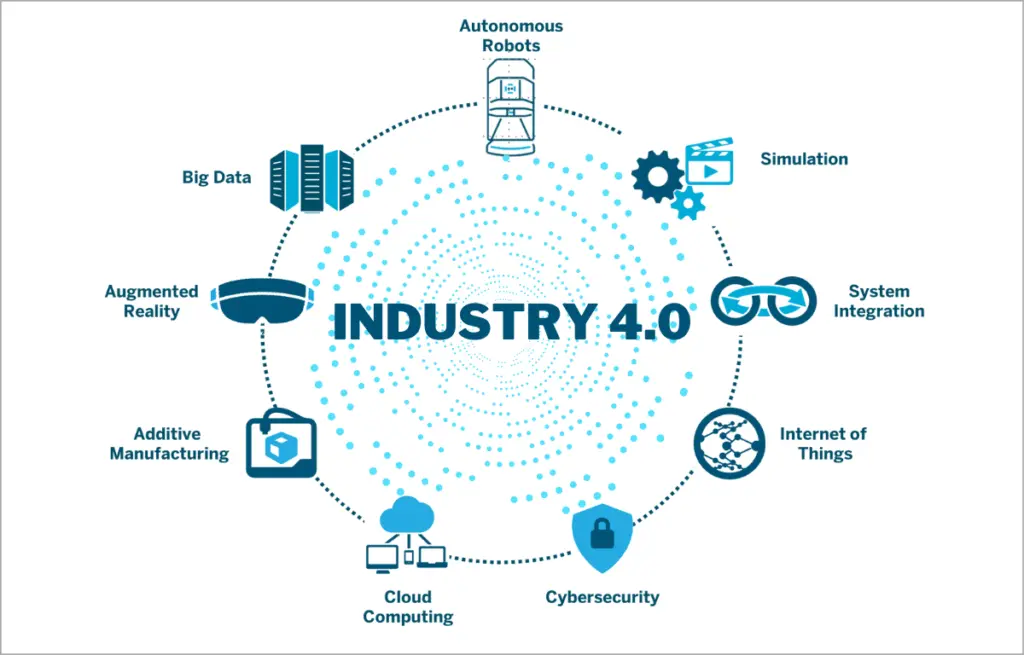

The industrial landscape is undergoing a significant transformation driven by Industry 4.0. This new industrial revolution leverages a convergence of technologies like artificial intelligence (AI), the Internet of Things (IoT), big data analytics, and automation to create a smarter, more connected, and efficient manufacturing environment.

Industry 4.0 is also fundamentally changing how businesses manage their supply chains, offering a glimpse into a future of increased visibility, agility, and optimisation.

Unveiling the Power of Industry 4.0 for Supply Chains

Traditional supply chains are often plagued by inefficiencies, limited visibility, and a vulnerability to disruptions. Industry 4.0 promises to address these challenges by introducing a range of transformative technologies:

- The Internet of Things (IoT): Industry 4.0 integrates physical assets with the digital world through IoT sensors embedded in products, machinery, and logistics infrastructure. This allows for real-time tracking of inventory, monitoring of production processes, and predictive maintenance of equipment. Imagine factory equipment sending real-time data on performance, enabling proactive maintenance and preventing costly downtime.

- Big Data Analytics: The vast amount of data generated by connected devices in industry 4.0 supply chains requires sophisticated analytics tools. These tools can identify patterns, predict potential disruptions, and optimise logistics planning. Imagine analysing historical data and real-time traffic information to predict delivery delays and adjust routes for optimal efficiency.

- Artificial Intelligence (AI): AI algorithms play a crucial role in industry 4.0 supply chains by automating tasks, making data-driven decisions, and improving forecasting accuracy. AI can automate repetitive tasks in logistics like order picking and fulfilment, freeing human resources for more strategic functions. Additionally, AI can analyse sales data and predict future demand, enabling businesses to optimise inventory levels and production planning.

- Blockchain Technology: Blockchain offers a secure and transparent way to track the movement of goods throughout the supply chain. This can be particularly valuable for industries with complex supply chains or concerns about product authenticity. Imagine a system where every step of a product’s journey, from raw materials to finished goods, is tracked and recorded on a secure blockchain ledger, enhancing transparency and preventing counterfeiting.

Benefits of Industry 4.0 for Supply Chains: A Symphony of Efficiency

Industry 4.0 offers a multitude of benefits that can transform the way businesses manage their supply chains:

- Increased Visibility: Real-time data from connected devices provides unprecedented visibility into every stage of the supply chain. This allows businesses to identify bottlenecks, track inventory levels, and make informed decisions about production and logistics.

- Enhanced Agility: Industry 4.0 empowers businesses to react quickly to changes in demand or disruptions. Predictive analytics can anticipate potential issues, while automation allows for more flexible production processes. Imagine a factory that can adjust production schedules based on real-time demand data, ensuring they have the right products in stock at the right time.

- Improved Efficiency: Automation and data-driven decision-making can significantly improve efficiency throughout the supply chain. This can lead to reduced waste, lower production costs, and faster delivery times. Imagine automated warehouse systems optimising storage and retrieval processes, resulting in faster order fulfilment and improved customer satisfaction.

- Optimised Logistics: Industry 4.0 enables smarter logistics planning by leveraging real-time data and AI-powered optimisation tools. This can lead to shorter delivery times, reduced transportation costs, and a more sustainable supply chain with optimised routes.

- Data-Driven Decision Making: The vast amount of data generated by industry 4.0 empowers businesses to make data-driven decisions rather than relying on intuition or guesswork. This can lead to more informed decisions across the entire supply chain.

Embracing Industry 4.0: A Journey of Transformation

Implementing industry 4.0 requires a strategic approach and investments in new technologies. Here are some key considerations:

- Digital Infrastructure: A robust digital infrastructure is the foundation for industry 4.0. Businesses need to invest in secure data storage, high-speed internet connectivity, and cloud computing solutions.

- Cybersecurity: With increased reliance on interconnected systems comes the need for robust cybersecurity measures to protect sensitive data from cyberattacks.

- Upskilling Workforce: The shift towards automation requires a skilled workforce that can manage and operate new technologies. Businesses need to invest in employee training and development programs.

- Collaboration: Industry 4.0 thrives on collaboration across the entire supply chain ecosystem. Businesses need to work closely with suppliers, logistics partners, and customers to leverage the full potential of these technologies.

Building a Future-Proof Supply Chain: The Catalyst for Growth

Industry 4.0 is not just a technological upgrade; it’s a catalyst for growth and a key driver of a more resilient and sustainable future for supply chains. By embracing the power of connected technologies, businesses can unlock a symphony of efficiency, agility, and optimisation.

This transformation journey requires a commitment to continuous improvement, investment in the right technologies, and a collaborative approach across the entire supply chain ecosystem.